updated 8/31/2023

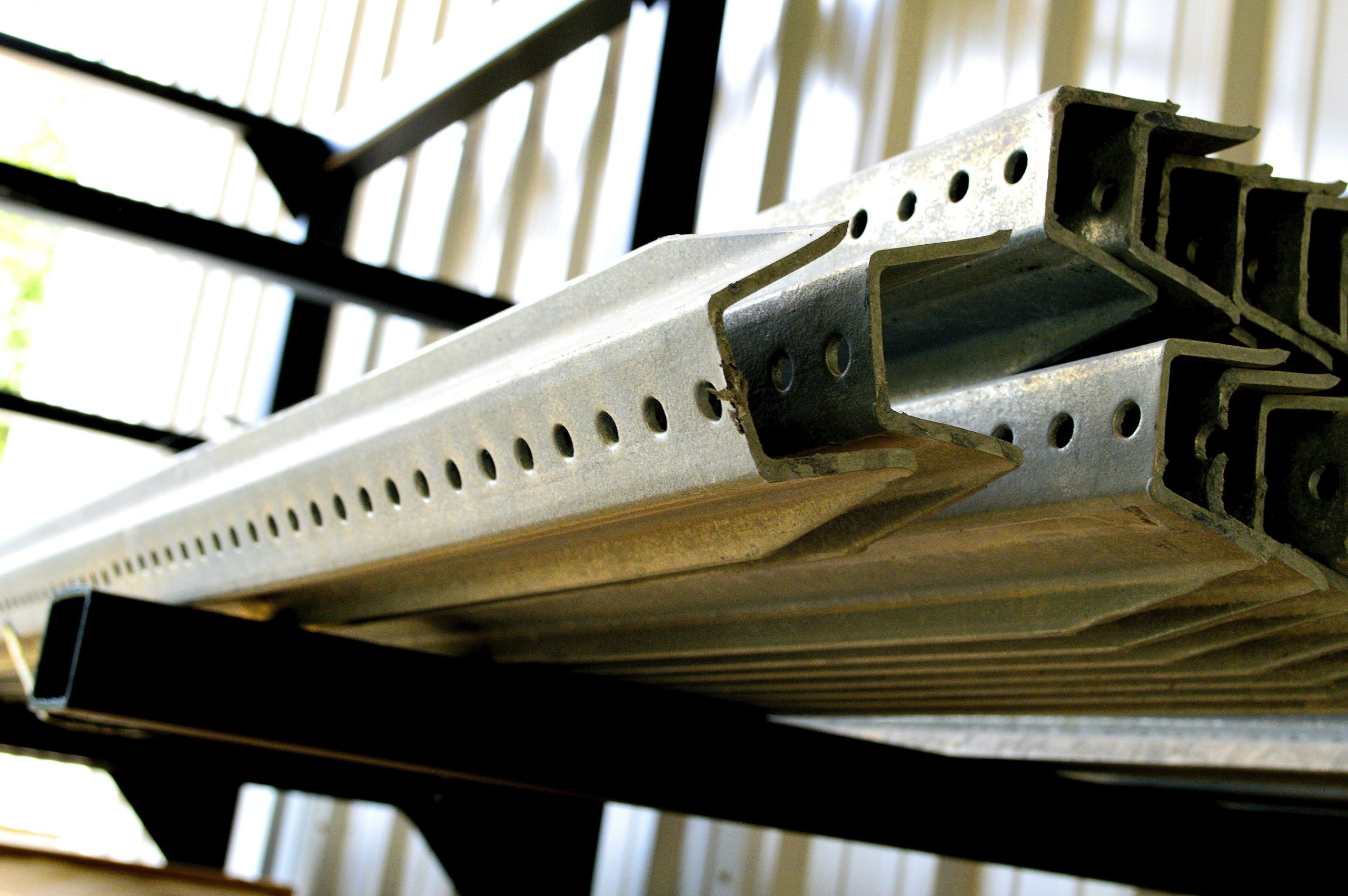

Sheet metal stamping dies are the parts responsible for cutting and shaping pieces made from sheet metal. Engineering diagrams provide specifications, and a trained diemaker creates the tool. The diemaker then attaches the die to the manufacturing equipment to produce the desired part.

Sheet metal stamping produces uniform parts, called piece parts, according to exact dimensions. This process is ideal for simple components.

The first step of the sheet metal stamping process is engineering. A developer generates drawings of the piece part, often using computer-aided design (CAD). An experienced artisan interprets the drawings to fabricate a one-of-a-kind die required to manufacture the piece part. The artisan then attaches the die to the press.

Blanks — manageable sizes of sheet metal — feed into the machine to begin the production process. The die cuts, bends and forms the part into the exact size and shape specified by the engineering diagrams.

The most common process in sheet metal stamping is cutting, which may include techniques like piercing and trimming. Forming is another process, and it involves compression, tension or a combination of the two to force the metal into the desired shape. Bending is one method of forming.

Since the stamping is machine-assisted, metal fabricators can produce consistent parts at high volumes.

The two types of die stamping processes you may encounter are progressive die stamping and transfer die stamping. What do these different types of stamping entail, and what are the advantages and disadvantages of each? What types of applications are most common to transfer die vs. progressive die stamping and vice versa?

In progressive die stamping, a coil of metal is fed through a machine that consists of a series of stamping stations that perform simultaneous operations. The metal strip moves through the drawing process, with each progressive die station altering the configuration on the metal from the previous station. Once the metal has gone through the entire machine and all the stamping stations, the piece will be complete.

Progressive die stamping is well-suited to operations needing to produce many small pieces quickly since you can perform multiple cutting and forming operations simultaneously. This combining of operations can also save on costs, although you will have to pay for permanent tool steel die sets. Progressive die stamping can also allow you to maintain close tolerances if you have the right tools.

You can find progressive die stamping in a variety of industries, including automotive, locomotive, heavy trucks and RVs, electronics, and agriculture.

In transfer die stamping, rather than feeding the metal part through a series of stations, a mechanical transport system transfers the part from station to station. The transfer die can be a single die or part of several dies lined up in a row. Transfer die stamping is used to perform operations on the part free from the strip.

Transfer die stamping tends to be more economical than progressive die stamping. It is also much more versatile than progressive die stamping. If your part has features like cut-outs, pierced holes, ribs, knurls, or threading, you can use transfer die stamping to work these into regular press operations so that you don’t need secondary operations at added cost.

You will use transfer die stamping when you have large parts you need to transfer between multiple presses to complete them, such as shells, tube applications, frames, and structural components. You can find transfer die stamping in all the industries where you find progressive die stamping. It all depends on the specific type of part you are stamping and your requirements for that part.