Caldera Manufacturing Group has decades of experience manufacturing/fabricating products from a vast range of raw materials. We manufacture 95% of our products from carbon steel, stainless steel or aluminum, in all grades and finishes. We can also work with materials such as brass, titanium, plastics and many others. In our more than 25 years in the industry, Caldera Manufacturing Group, formerly Summit Steel, has developed extensive expertise in fabrication projects using a wide variety of metals.

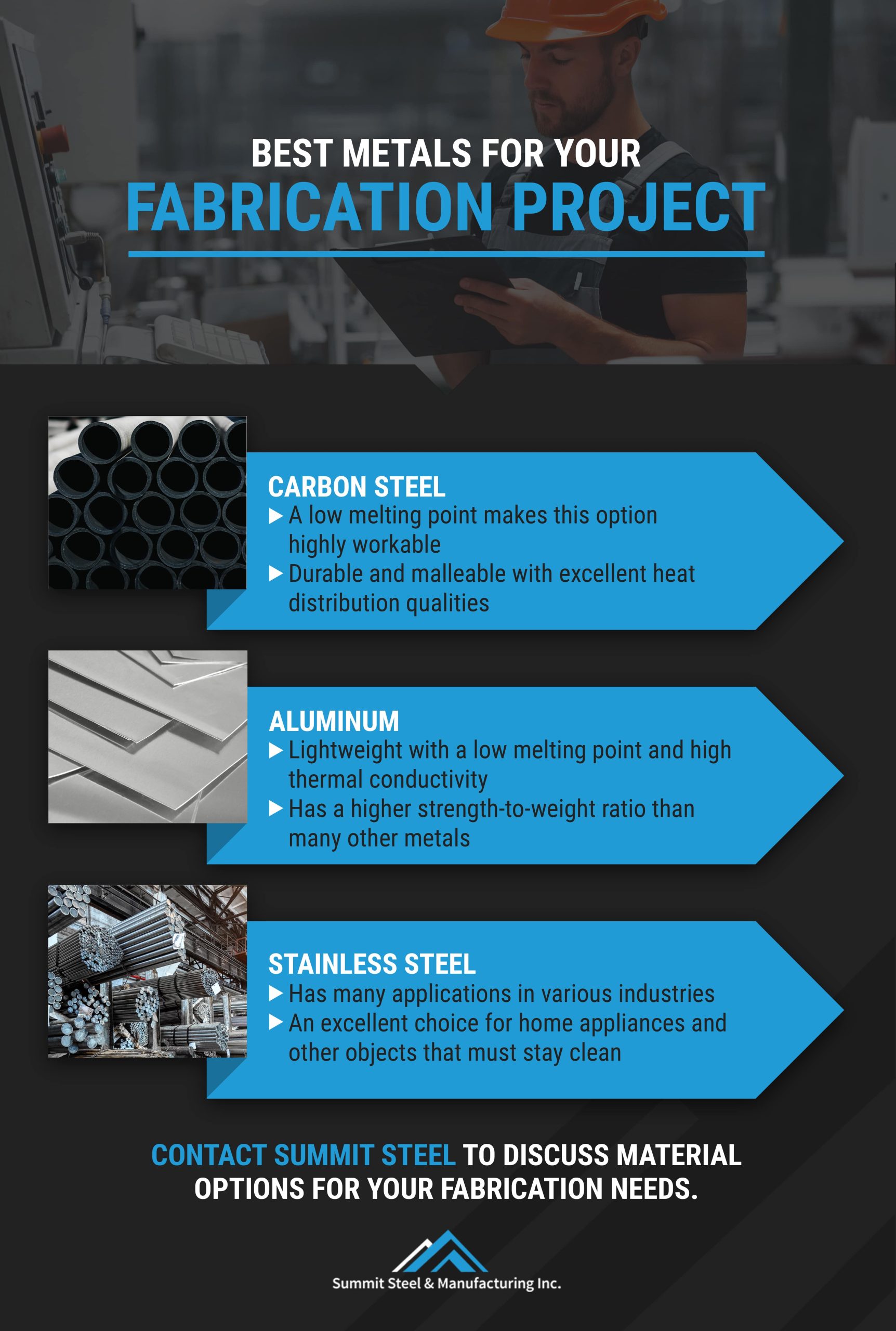

Carbon steel contains more carbon than traditional steel alloys. That percentage gives carbon steel a lower melting point and makes it highly workable. Consumers in various industries choose carbon steel for metal fabrication for this reason. Carbon steel is also malleable, durable and has excellent heat distribution qualities. Based on its composition and production technique, carbon steel falls into the following categories.

Both carbon and stainless steel are iron alloys. Iron oxidizes, which causes corrosion. However, stainless steel contains chromium, making it more resistant to corrosion than carbon steels. Stainless steel has countless applications in any industry. It is the most popular choice of materials used in metal fabrication for home appliances and other objects that must stay clean.

Many consumers choose aluminum for products that require lightweight metal fabrication materials. It has a low melting point and high thermal conductivity. Despite some of its weaker mechanical properties, aluminum has a higher strength-to-weight ratio than many other metals. It is common in metal fabrication for architecture, solar equipment and cars.

Are you interested in other metal materials used in fabrication? We can also work with titanium, brass and copper, to name a few, so please contact us to discuss the products you would like to manufacture and potential material options.