From chip readers to artificial intelligence (AI), technology is continually advancing — and no industry remains unaffected by it. In fact, rapidly evolving technology in the manufacturing industry has stratified the playing field so drastically that many manufacturers are struggling to keep up.

With advancements in all levels of the manufacturing process, from prototyping to production, companies in the metal industry are faced with countless opportunities for technological improvement. Especially in regards to digital technology, experts agree that manufacturing companies should embrace the latest tools and techniques to keep themselves ahead of the curve and distinguish themselves from competitors.

To some, technology can seem intimidating, but it’s crucial that manufacturers implement new advancements in digital and robotic technology in order to optimize their operations. Here’s why we believe that every manufacturer should keep their production technology up to date:

Over the past decade, manufacturing technology has yielded exponentially higher productivity rates across nearly every subset of the manufacturing industry. For example, the rise of smart robotic technology in manufacturing has drastically increased output and cut down on human error, which has, in turn, translated to increased company revenue.

Advancements in information technology have greatly benefited manufacturers as well. Digital communication platforms and data management software (think enterprise resource management, or ERP) have enabled manufacturing companies to more quickly and accurately manage inventory, quality control issues, worker training and much more. Streamlining communication and data management increases both efficiency and precision throughout the manufacturing process.

Technological advancements in manufacturing have accomplished many major wins — one of them being better product quality overall. Amid the increasing demand for highly customized products, manufacturers need the right production technology to keep up.

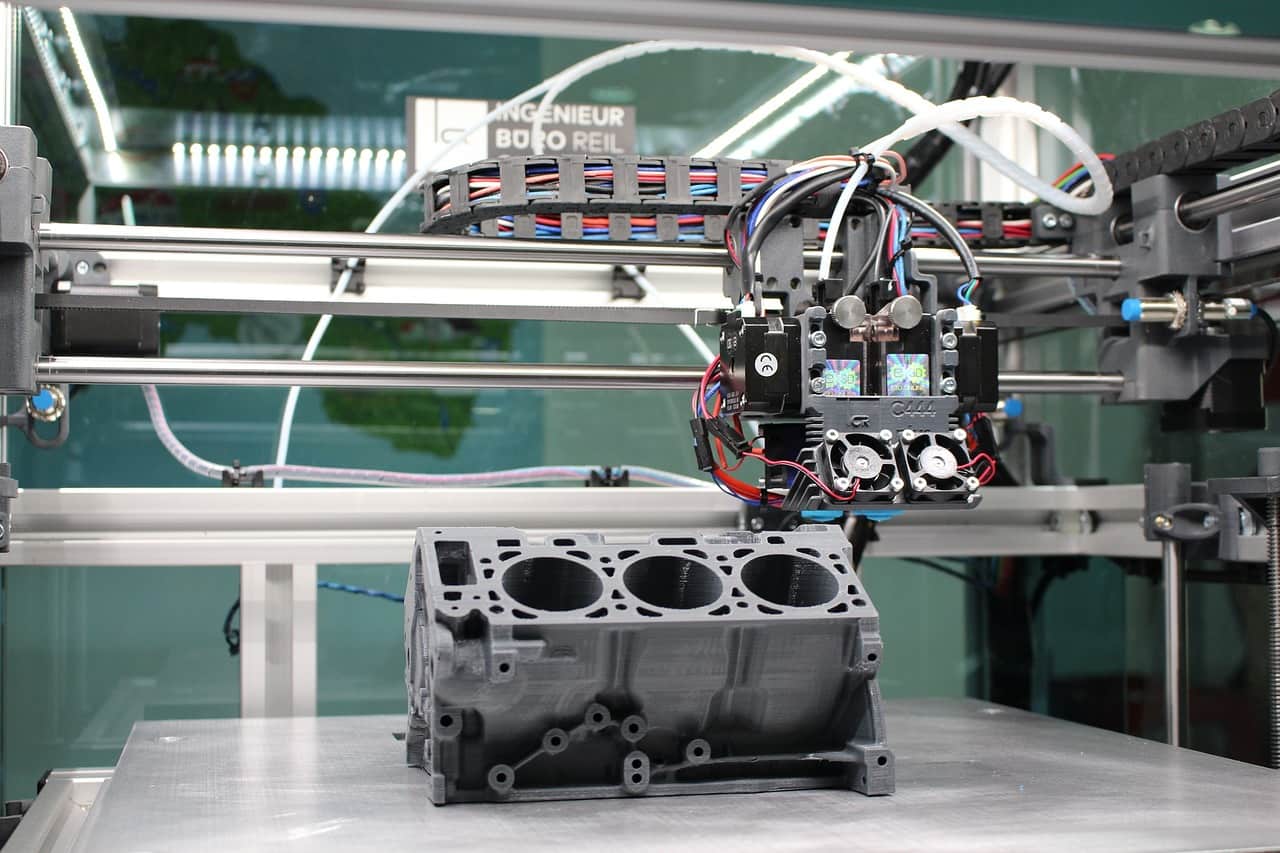

One way that manufacturers can meet this demand for highly customized components and products is by implementing robotic technology during the production process. In addition to speeding up production, today’s robots can use machine vision technology to increase their fabrication and welding efficiency and better adapt to switching tasks.

Manufacturers are also being more frequently tasked with making complex physical components that integrate into Internet of Things (IoT) technology, consumer electronics and other products that are shaping the Digital Age, requiring them to perform operations with greater precision.

The manufacturing industry can benefit tremendously from implementing advanced digital and robotic technology. If manufacturers stay ahead of the technology game, their ROI will be well worth the new technology cost and learning curve. Embracing technology in manufacturing provides the following overall benefits for metal manufacturing companies: