All metals showcase different levels of strength, hardness and corrosion resistance. High-volume metal fabrication companies typically handle the following materials to match your vision for tools, equipment, structures and more:

Steel materials are involved in construction fields due to their exceptional durability. Fabricators recommend using steel when a business is on a strict budget but requires versatility for welding. Steel offers an exceptional strength-to-weight ratio and is malleable enough to take on virtually any shape. From support beams to weaponry, steel has a permanent home in the fabrication world.

Stainless steel is frequently used for high-volume metal fabrication because of its corrosion-resistant properties. This metal offers a distinct shine, is easy to clean, and sees widespread use in everything from kitchen appliances to medical instruments.

Aluminum is a cost-friendly material that can be cut and machined into unique shapes. Fabricators will use aluminum because it bends quickly to a client’s specifications, and sheets remain strong in freezing temperatures. A project manager might use aluminum for refrigeration products and aircraft parts.

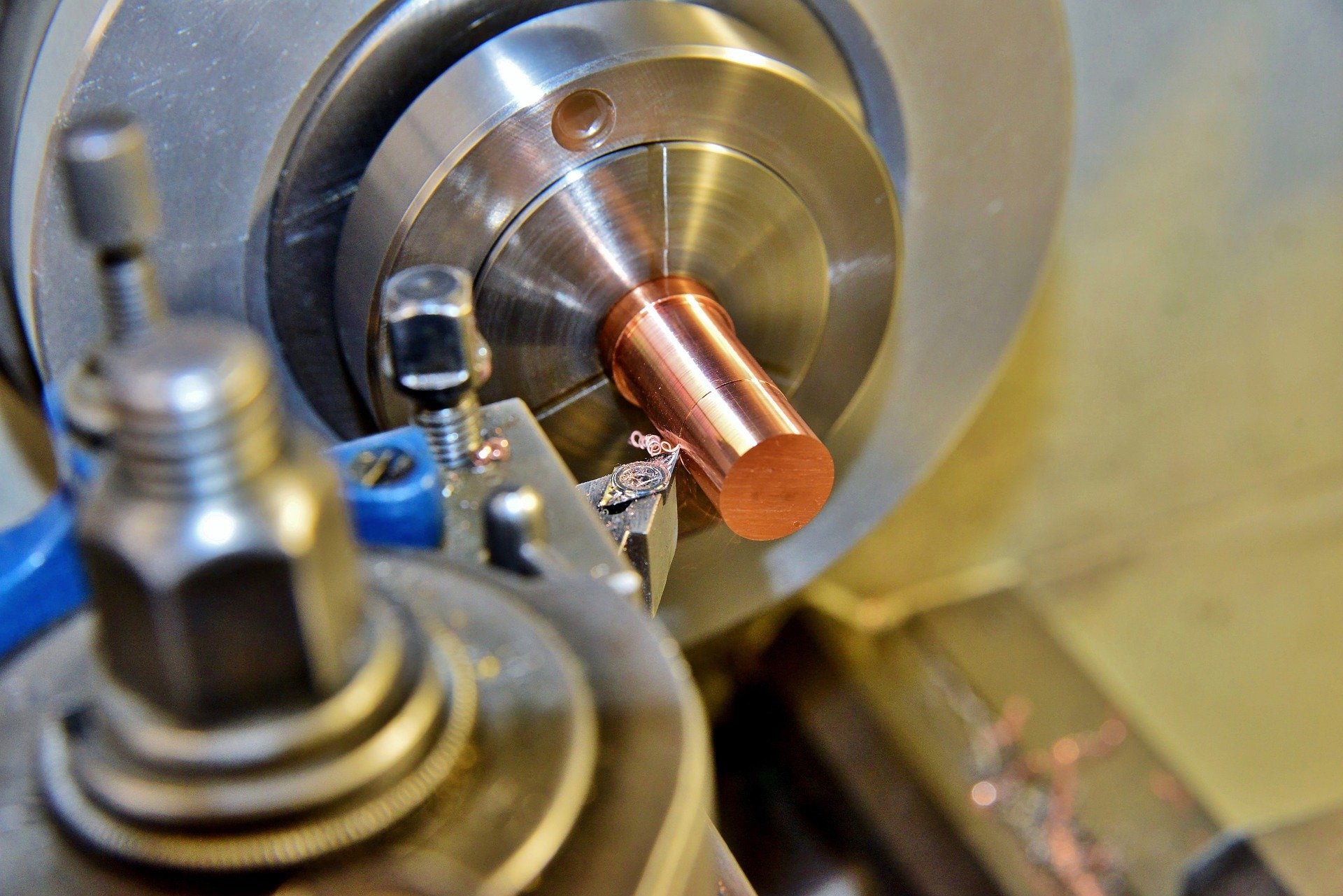

Copper plays an important role in contract manufacturing because of its electrical conductivity and attractive finish. High-volume metal fabrication shops are quick to use copper for its malleability and resistance to rust. Businesses can fabricate copper to create bathroom fixtures, boating gear, industrial platforms and more.

Brass is less expensive than copper and performs well in high-temperature settings. The metal is resistant to electricity as well, making it ideal for automotive parts and hardware pieces that might be exposed to friction or sparks.

Selecting a material for metal fabrication requires business owners to think about product cost, appearance and performance. It’s best to choose a metal that suits your budget and the end product’s intended use.

A high-volume metal fabrication company like Caldera Manufacturing Group, formerly Summit Steel, will help you pick the right metal after hearing more about your vision so that each product is safe under real-world conditions.

Picking the right metal for fabrication involves assessing various physical properties. You want to use a sheet metal material that can provide long-term results for your applications with a finish that is pleasing to the eye. Professional fabricators use the following criteria to help you make a final decision for production manufacturing efforts: