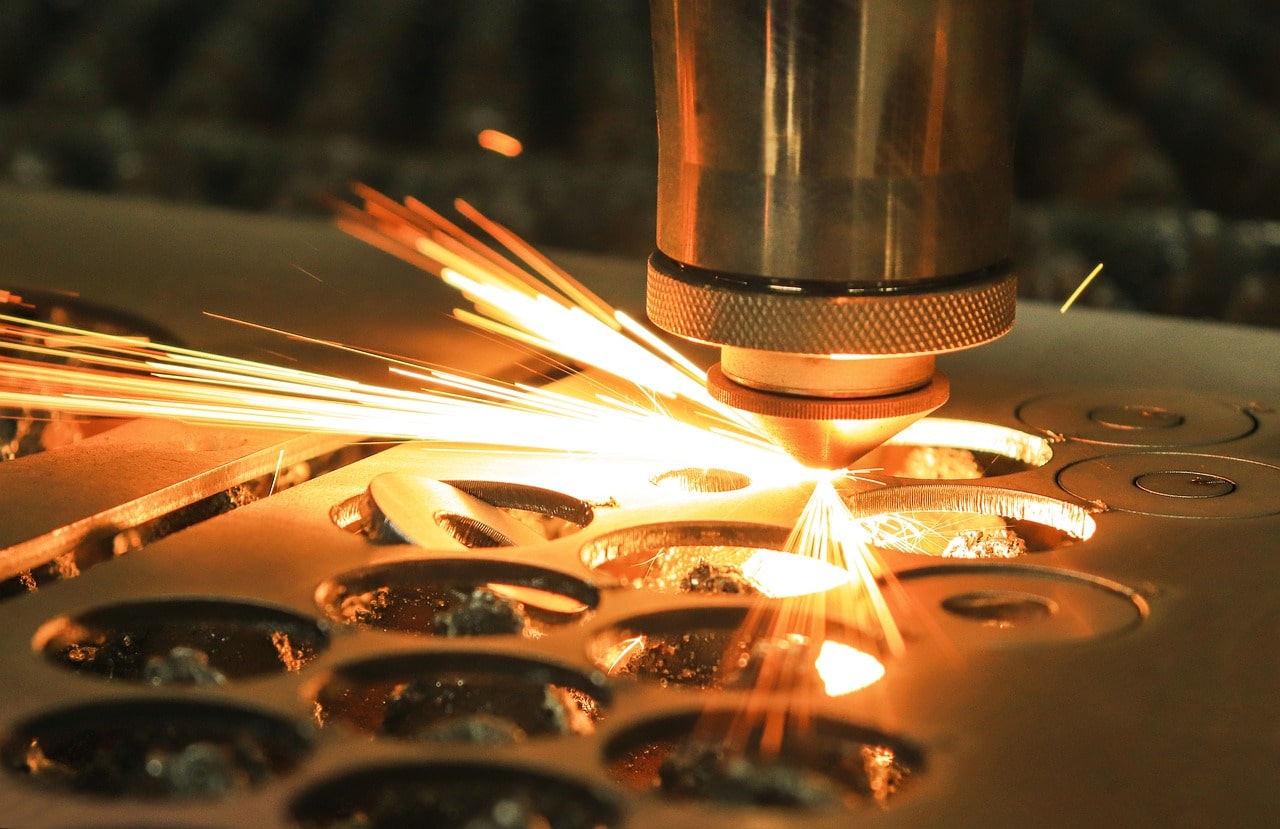

Operators can use a turret punch or laser cutter to cut through material during sheet metal fabrication. With developments in both technologies, manufacturers can use both machines effectively in the right context. Many operators now focus on laser cutters because of their newer capabilities, but turret punches also have plenty of utility. An experienced operator can perform high-quality work with either of these machines. This blog post will review each machine’s capabilities in sheet metal fabrication.

Turret punches and laser cutters process sheet metal into parts by cutting the material. Learn more about each process:

Each machine suits different situations better than the other. A turret punch can fit more applications than some professionals may think.

A turret punch and laser cutter can have similar levels of versatility, depending on the model used. Generally, laser cutters can cut into thicker material than turret punches. Advanced turret punch models have stronger cutting power that allows them to work with more metals. Turret punches can perform more secondary operations than laser cutters, including:

With a turret punch machine, a fabrication shop can save time and money on processes that laser cutters cannot handle.

Compared to a laser cutter, a turret punch has a more economical price and can perform more tasks. These factors combined lead to higher cost competitiveness for turret punching than laser cutting. When a business chooses a fabrication company that uses turret punching, the savings pass on to their project costs.

On average, a turret punch makes fewer hits per minute than a laser cutter, but additional factors improve its efficiency. An advanced laser cutter can perform 10,000 hits per minute compared to turret punching’s 1,000. However, a turret punch’s versatile capabilities and reduced lead times can make up for the fewer hits per minute.