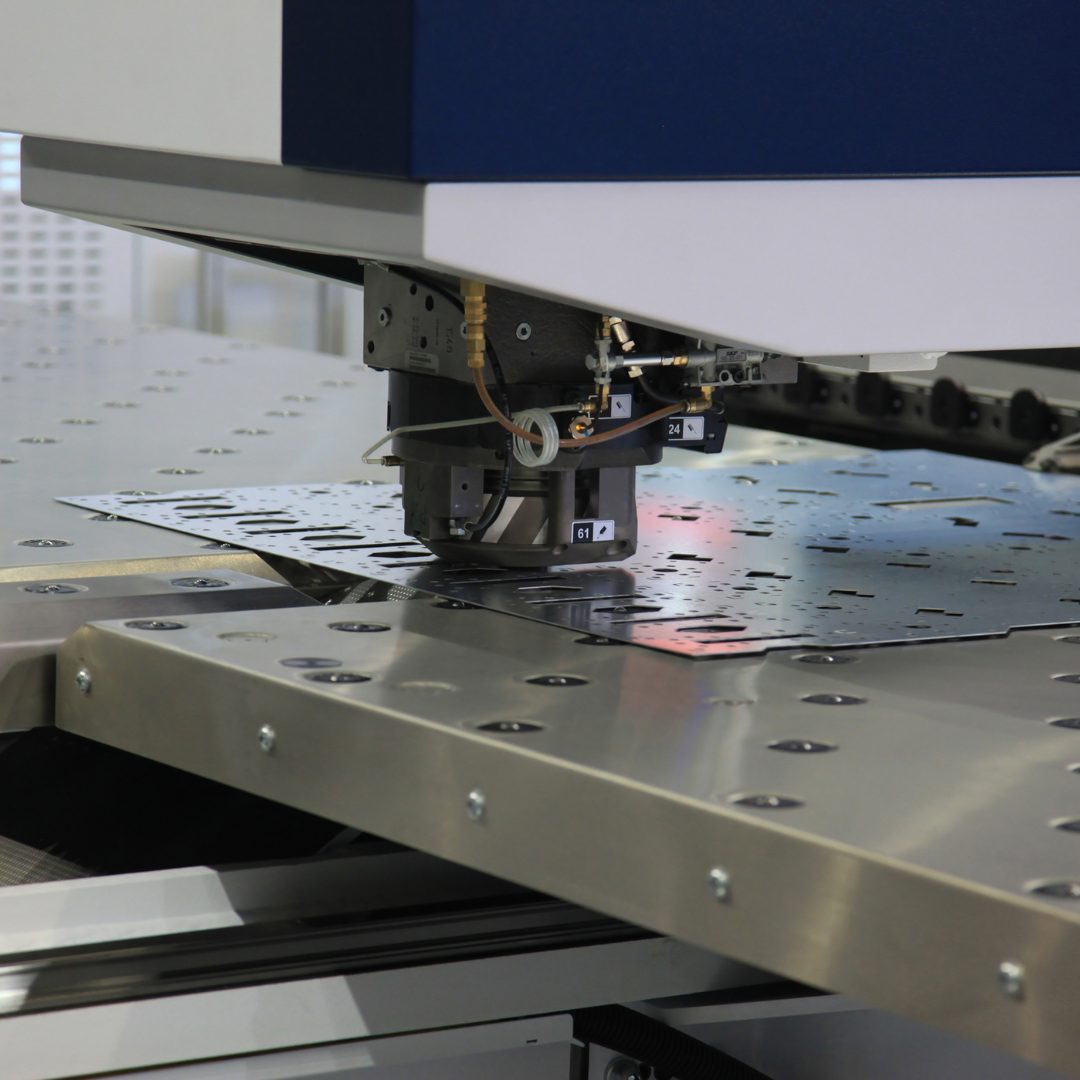

At Caldera Manufacturing Group, our computer numerical control (CNC) turret punching services enable us to create a diverse range of components, from perforated metal sheets to complex parts.

Learn More

CNC turret punching is a metal fabrication process that uses a rotating automated turret to punch holes in a metal sheet to prepare it for later production steps. By swapping out the punch tool, the operator can create holes of various shapes and sizes, including custom pieces.

Precision CNC punching is well-suited to high-volume projects because it maximizes speed without sacrificing quality. It’s not typically a cost-effective choice for small runs due to the tooling costs involved.

Some of the many benefits of our CNC turret punching services include:

Our 100,000-square-foot facility contains state-of-the-art technology and equipment, enabling us to work with a wide variety of materials such as:

We work to your specifications — whatever needs you have, our team can meet. Schedule a consultation with one of our experts to learn more about our capabilities.

CNC turret punching enables rapid mass production using almost any hole shape or size — which means you can build inventory and boost your bottom line faster than with many other fabrication techniques.

At Caldera, we serve customers across a wide variety of industries, including: