CNC Machining Applications & Benefits

CNC Machining Applications & BenefitsCNC machining is a tried and trusted method of metal fabrication used for countless projects every day. Nearly anything that requires engineering or planned design most likely involves CNC machining in some way. All kinds of industries and businesses need quantities of large and small metal and plastic components that may become part of anything from automobiles to zoos.

If you’re reading this on a computer or handheld device, it probably contains something created by CNC machining. If you drive a car or have machines in the garage, they are likely to have components produced with CNC machining. The process started in the 1960s and has since grown to encompass a multitude of metal fabrication applications.

There is much to gain from learning about the CNC machining process and how it can benefit your unique business application.

CNC refers to computer-numerical control machining, and it automatically operates machine parts including lathes, routers, grinders, shapers, mills and more under the control of a computer instead of a human operator. Compared to manual operation, CNC machining reaches an exponentially faster and more precise level of production through multitasking. The process employs several axes at once to accomplish the jobs.

CNC machining involves exact, high-speed movements that enable expedited production, customization and several opportunities to gain benefits. CNC machining most often involves doing the jobs of lathes, routers, mills and grinders, and it encompasses bending, forming, turning, Swiss-style machining and other processes as well.

CNC machining prompts many gains and few losses. The advantages of CNC machining apply to companies offering the service and to the clients who seek them. This tends to generate some benefits. A few of these benefits include:

There are a few disadvantages that may deter some businesses from choosing CNC machining:

You can rely on CNC machining for an endless number of applications within a full range of materials such as aluminum, carbon and stainless steel, titanium, brass, castings, plastic, wood, gold, silver and synthetic materials including ABS, polycarbonate and others. The call might be for tons of tiny metal plates bent to a certain angle and engraved with a number, or for a large panel punched to order.

A business might need fittings, spacers, bushings, shafts, manifolds, dies, fixtures, molds and any number of other parts. A huge benefit of CNC machining is how it not only performs in all kinds of environments, it enhances the business’s overall bottom line by doing the job faster and more cleanly than any other method.

Many essential metal fabrication tasks are made easier and faster with CNC machining:

The full range of capabilities CNC machining delivers makes it possible to create just about anything part or tool a business needs.

All kinds of businesses need precisely machined parts with unfailing consistency. Countless industries use CNC machining for their metal fabrication needs, including:

Aerospace: Every industry needs precision, but it’s especially important aircraft travel parts, such as an aircraft turbine engine, for example. Without precise parts, air travel for humans and goods could not be reliable and safe. Aerospace favors CNC machining because it offers the five-axis CNC machining needed, which can manage such hard-to-cut materials as Inconel.

Automotive: Think of all the shafts, gears, pins, brackets and other parts that are used on vehicles of all sizes and styles. From specialized auto to military vehicles, CNC machining answers a call for the large and small parts that keep the production lines moving.

Construction: The tools and equipment used to construct things, as well as the materials used to build them, inherently involve CNC machining. It’s a part of most building processes by nature of the wood, stone, nails, screws and other items used to create a structure. It might also be the answer to a desired architectural style, such as relief statues, or it could be needed for safety compliance or aid, such as with textured handrails.

Dental: Dental implants need machining to be just exactly the right shape. Besides the items that are surgically implanted, there are also the tools the doctors and assistants use. CNC machining puts just the right point, angle or bend on the business end of the instruments, as well as the texture on the handle that helps the professionals keep their grip.

Electronics: The brains inside most computers, the motherboards, have millions of tiny parts that must work with consistency and reliability every time. The intricate hardware of electronic items has rows of metal slats, panels, tiny wires, engraved numbers and other details that CNC machining serves well.

Electrical: An electrician’s crew comes across dozens of things in a day that involve CNC machining, from cut coils and breaker panels to light fixtures and decorative items.

Food and Beverage: Each time we push the bar at a convenience-store soda fountain or eat in a restaurant, there was or is CNC machining involved in serving our needs. It’s more than likely that every place that makes or serves food and beverages is intimately familiar with the technique and its capabilities.

Equipment: Light and heavy, big and small, all equipment alike involves CNC machining in one form or another. CNC machining might not be solely responsible for the creation of a huge earthmover, but it certainly it would be involved in many stages of its creation. The texture and size of fasteners, the shape of a crowbar, the gentle angles of a garden spade and its blade are all examples of tools and equipment CNC machining helps create.

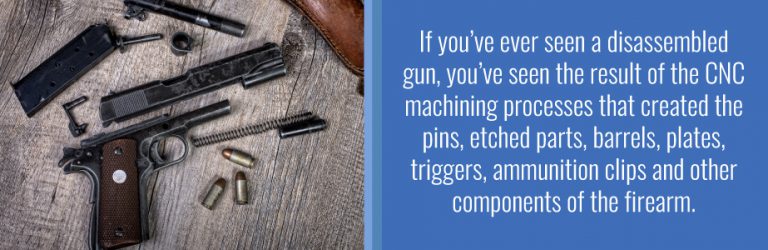

Firearms: Weapons of all kinds may require CNC machining, but especially firearms. If you’ve ever seen a disassembled gun, you’ve seen the result of the CNC machining processes that created the pins, etched parts, barrels, plates, triggers, ammunition clips and other components of the firearm.

Military: Broad needs for CNC machining exist within the military, where nameplates and defense implements might be on the same purchase order. The precision and uniformity produced by CNC machining fits so many aspects of the military’s nature, from its mighty instruments of war to its rows of identical buttons.

Printing: Commercial and newspaper printing plants use CNC-machined parts throughout their facility. The Newspaper printing presses and the ad-insert machines that work every day to produce the periodicals people expect to see were all partially created by CNC machining.

Manufacturing: Anywhere people are making something on a production or assembly line, there is probably CNC machining involved at several or all points. Levers, plates and panels are just a few of the big and small parts that keep production facilities running smoothly.

Transportation: Nearly all modes of ground transport use CNC machining, including rail, over-the-road trucking, transit and others. From the large sheets that make up the bodies of vehicles to the tiny circuitry and other electronics involved in transportation, it takes an array of CNC machining to keep all these vehicles running.

More applications of CNC machining work include multi-axis machining, where objects that would normally need to be cast are created from a solid piece of metal or other material. CNC processes routinely incorporate plasma and laser cutter technology, too.

Computer-aided design software produces a three-dimensional model of the final component, and the model can then be loaded into the system to program the machining and produce exact replicas. Once a template has been fed into the system, those same, exact replicas can be produced quickly and easily again and again.

Some mourn the loss of manual lathing and milling techniques, but these techniques are bound to persevere and even flourish outside the high-production environment. The growth of CNC machining, in fact, has led to the growth of new industries as well as educational courses geared toward CNC programmers and operators.

The field of programming or operating CNC machines has been a growing career path for as long as the craft has been around, but even more so with the dawn of the data age. It pays a decent wage, and good programmers and operators are always in high demand.

It’s worth knowing how product quality is dependent on proficient CNC programming and operation. As you can imagine, if either one is off even a micro-fraction, it can cause problems. CNC machining providers should be scrutinized the same way any other commercial service vendor is, since the result of your product will be directly affected by the quality of a provider’s operators, programmers and equipment.

While the industry and application may vary from business to business, CNC machining is a process that helps them all to do their jobs and accomplish efficient production.

Caldera Manufacturing Group, formerly Summit Steel, offers a full range of CNC machining services that touch many applications across dozens of industries. We offer a complete range of metal fabrication solutions, making us your one-stop shop for any metal contract manufacturing needs. You might also need turret punches, stamps, fabrication, bending or assembly, all of which we can accommodate.

We produce solutions using welders certified by ISO 9001-2008 and AWS. Caldera Manufacturing Group’s CNC programmers and operators have deep knowledge and experience to share and apply to your project, and we invest in high-quality equipment.

Our welding division is outstanding, and robotic, computer-programmed capabilities enable us to offer the reliable and precise welds industry needs. We recognize the importance of high-quality welding, so we dedicate considerable time, energy and resources to stay abreast of the current and efficient technology, trends and regulations.

Our experience in the business spans 20 years, which we’ve used to refine our skills and sharpen our tools. It makes all the difference to team up with a company who focuses on short and efficient lead times, shipping and other logistics. An experienced CNC machining company can positively impact your quality, process and ultimately, your bottom line.