You may hear the phrase “CNC machining” in your industrial or manufacturing application. This computerized machining process allows for the precise and efficient use of factory machines and tools. Learning more about this technique can help you understand how to outsource it for your project effectively.

CNC Machine Definition — What Are CNC Machines?

Computer numerical control (CNC) machines use directions from a computer to complete machining processes. Machining equipment takes a stock piece of material and cuts away parts of it to achieve the specified results. CNC machining counts as a subtractive manufacturing process, or a technique that removes layers of material to create the desired shape. The different types of CNC machines include:

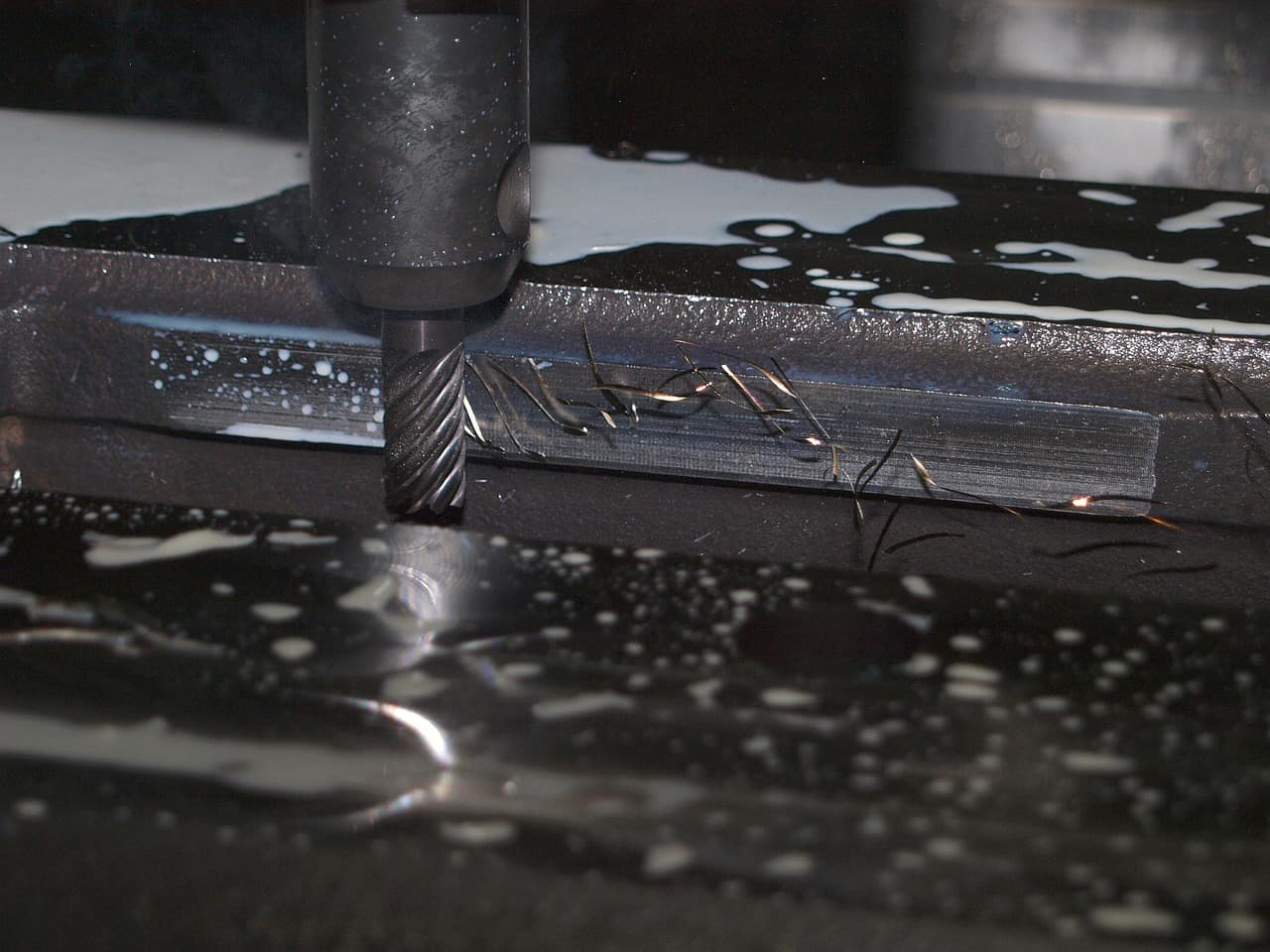

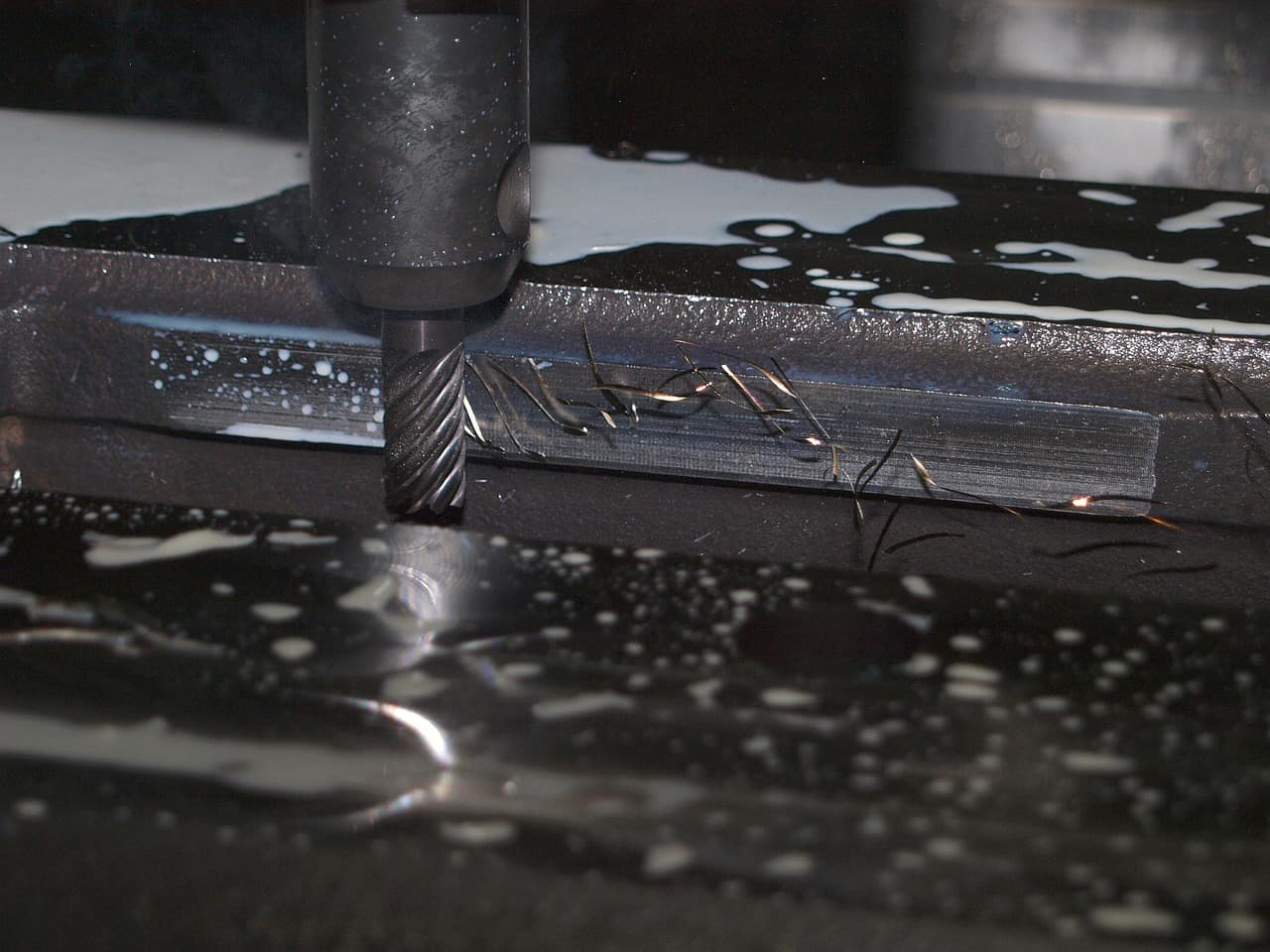

- Milling machines: Milling machines use a rotary cutter to remove material.

- Drills: A drill spins a drill bit against the material to create holes and other shapes.

- Lathes: Lathes gradually spin material against a cutting tool to shape it to specifications.

- Waterjet, laser and plasma cutters: These machines use advanced technology to cut parts out of sheet metal.

CNC machines automate many machining tasks at a high level of precision, making them suitable for high-volume projects.

How Do CNC Machines Work?

A CNC machine follows directions from a pre-programmed computer software. This program specifies the machine’s speed, movement and position to achieve a specific material shape. The CNC machining process features the following steps:

- Working in CAD: The designer creates a 2D or 3D drawing in computer-aided design (CAD) software. This file includes specifications such as the structure and dimensions that will tell the CNC machine how to create the part.

- Converting the CAD file to CNC code: Since CAD files find use in many applications, the designer needs to convert the CAD drawing into a CNC-compatible file. They can change the CAD format to a CNC format with a program such as computer-aided manufacturing (CAM) software.

- Machine preparation: Once the operator has a readable file, they can set up the machine itself. They attach the appropriate workpieces and tooling for the program to execute correctly.

- Process execution: With the files and machine prepared, the CNC operator can execute the final process. They start the program, which then guides the machine through the entire process.

When the designer and operator complete this process correctly, the CNC machine can perform its tasks efficiently and accurately.

Computer Numerical Control (CNC) Machine Applications

CNC machines find use in a variety of applications due to their versatility. In an industrial context, CNC machines can perform:

- Manufacturing processes: CNC machines can expand the capabilities of manufacturing businesses in need of automated processes.

- Rapid prototyping: A CNC machine can quickly create prototype parts with a high degree of precision.

Since CNC machines can handle 2D and 3D designs, they have a wide range of applications in multiple industries.