The automotive industry is continually making advances with the use of automation and robotics to improve automotive production and design. CNC machining is the newest automated technology to transform automotive manufacturing processes.

The automotive industry is continually making advances with the use of automation and robotics to improve automotive production and design. CNC machining is the newest automated technology to transform automotive manufacturing processes.

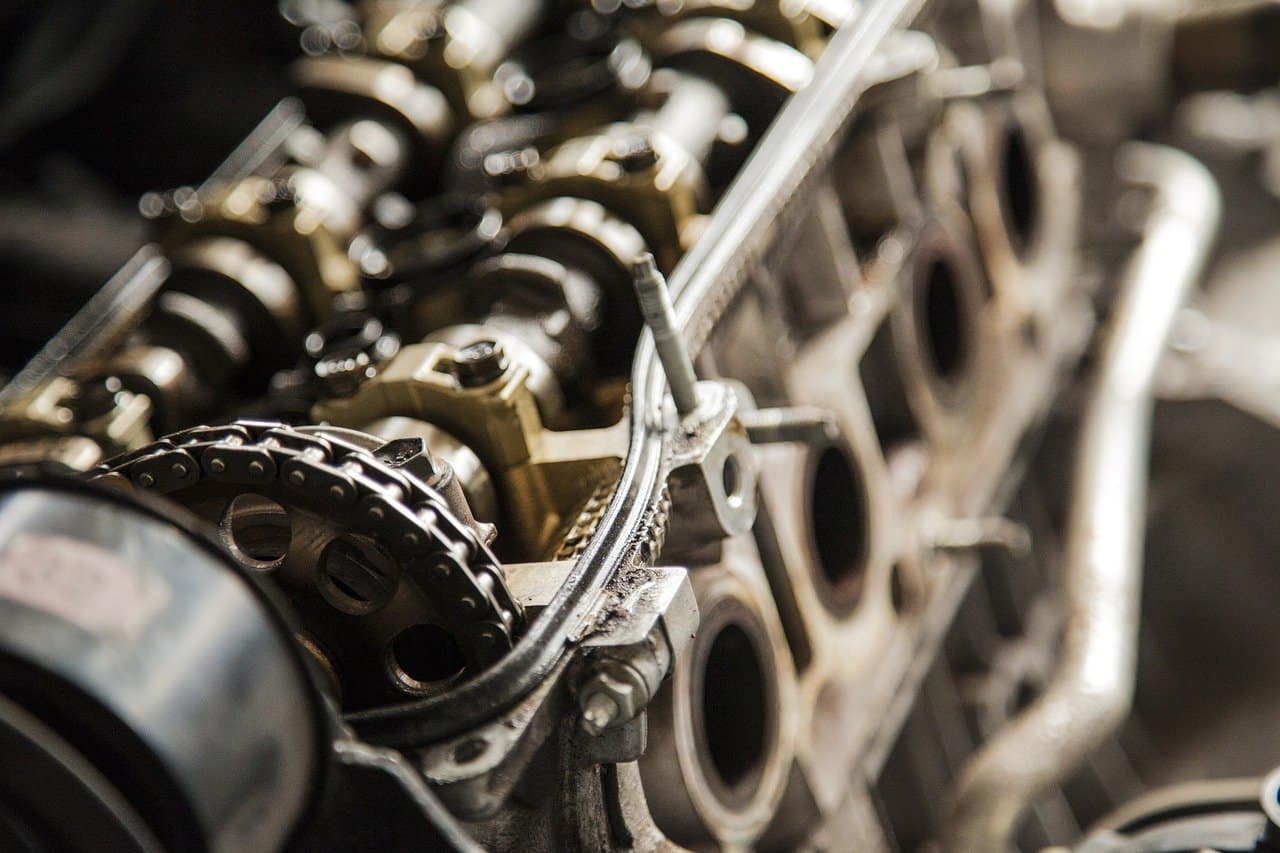

Computerized Numerical Control (CNC) machining is a computer-controlled manufacturing process for producing precise parts using many different materials, from plastics to metals and more. To create the parts, CNC machines send computerized instructions to motorized tools such as a lathe or drill. The tool uses those instructions to turn a block of material into the finished product.

This process can be used in automotive production to create engine parts, interior and headlight lighting, suspension components, carburetor housings, exhaust parts and more.

There are many advantages to using CNC machining in the automotive industry, including:

CNC machining is undergoing further innovation with the use of artificial intelligence (AI) in CNC machines. AI helps to reduce downtime and maintain consistent, high-quality output, with automatic adjustments made when necessary.

AI-assisted CNC machining is also increasing and enhancing the production of self-driving cars. With the help of AI, CNC machines can be used to design components with a feedback mechanism to help the cars self-drive.

As this technology continues to develop, AI will likely become smart enough to connect with CAD software and correct design errors. Eventually, AI-assisted CNC machines could be able to improve and generate automotive part designs.